The Right Treatment for Food Processing

Burnette Foods, a Michigan company and one of the nation’s leading producers of shelf-stable fruit and vegetable products, needed a new wastewater treatment system at its East Jordan plant to comply with updated requirements from the Michigan Department of Environment, Great Lakes & Energy (EGLE). Windemuller worked with the client to revamp a pre-bid design into a system that functioned better while still leveraging equipment that Burnette Foods already had onsite.

Throughout the Generations

Based in East Jordan, Michigan, Burnette Foods, Inc. is a three-generation, 50-year-plus food processor and producer known for making shelf-stable fruit and vegetable products. Today, Burnette Foods is one of the nation’s largest producers of shelf-stable fruits and veggies, with products that include fruit juices, apple cider, applesauce, fruit cups, canned fruits and vegetables, fruit fillings and toppings, and more.

Meeting All Requirments

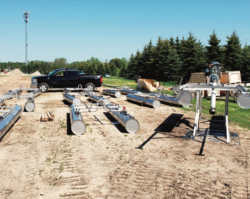

In 2019, Windemuller sought out a project with Burnette Foods as part of a public bid process. The job involved designing a new wastewater treatment system for the Burnette Foods East Jordan food processing plant—a necessary step to facilitate new EGLE requirements for wash water from fruits and vegetables being processed by the plant. Even before the bidding process, the customer already had a design in hand that they wanted to move forward with. During the post-bid interview with Burnette Foods, though, Windemuller realized that there were many holes in the original design. Sensing that the customer was not completely satisfied with the initial design, we convinced them to let us start over and do a full design-build for electrical and automation.

The Challenge

The inherent challenge of this particular project was coming into it expecting to do a buildout and then quickly realizing that a new design would also be necessary. That revelation also created another challenge: that of budgeting. The original budget for the project was $385,000, and our goal was to deliver a new and superior design that met the client’s needs without drastically increasing the price tag.

The other challenge was COVID-19. While less impacted by the pandemic than many of our other 2020 projects, this job was still in its early stages when coronavirus hit and forced shutdowns of workplaces and worksites across America and around the world. We had to work around those hurdles to finish out the project without a significant delay.

The Solution

Resourcefulness was the name of the game for this project. To maintain budget and still deliver results, we took the owner’s intent and the basic framework of the original design and planned out a wastewater treatment setup that would work with the equipment and systems that had already been purchased for the job. From there, we leveraged our in-house expertise in electrical, automation, and process design to meet all the client’s needs.

Even across the Windemuller company footprint, this project took on a sort of all-hands-on-deck approach. For instance, automation experts at our Wayland office set to work on the two control panels necessary for the project: MCP1, for the main building that housed the main controls and lift station; and CP2, which housed the controls for the lagoon aerators along with the influent lift station. Once the panels were complete, a team from our Traverse City office took the baton to handle the programming and startup for the panels, and to work alongside our electrical crews on installation.

Ultimately, we were able to keep the project close to the initial budget while still expanding the scope and programming significantly. We worked closely with Burnette Foods throughout—particularly their plant engineer Kevin Kalchik, who acted as the general contractor on the job. Kevin was very happy with the build quality of our control panels, with our willingness to work with Burnette Foods on crafting a new design, and with our responsiveness when it came to solving any and all issues that came up during construction. Even despite COVID-19 hurdles, we were able to stick to the revised timeline and deliver a compliant solution to Burnette Foods that met and exceeded their every expectation.