Solution for a Tall Order

Founded in 1956, the Flex-N-Gate Corporation is a manufacturer of automotive parts. Though the company initially started as an aftermarket part maker, it grew and evolved over the years into one of the automotive industry’s most dependable parts suppliers. Today, Flex-N-Gate works with companies like Ford, GM, Toyota, Subaru, and Fiat Chrysler Automobiles. These companies have repeatedly honored Flex-N-Gate with “supplier excellence” or “supplier of the year” awards.

Flex-N-Gate has multiple divisions with various different capacities. It manufactures plastic parts, metal parts, lighting components, and mechanical assemblies, all in the automotive space. For this project, Windemuller was contracted to help with a new 45,000-square-foot metal stamping addition at Flex-N-Gate’s Battle Creek factory.

Windemuller’s responsibilities for the project included site work, major power distribution – with primary work, site lighting for several parking lots, fire alarm installation, and interior lighting with daylight harvesting.

The Challenge

Windemuller ran into numerous challenges on this project, including:

- Meeting strict deadlines on the site work

- Doing underground installation work in site soils that were extremely rocky

- Coordinating with many other trades, while also racing to meet the project’s tight deadlines

- Working around the project owner’s subcontractors, who were installing the stamping presses for the plant addition while the rest of the project work was going on

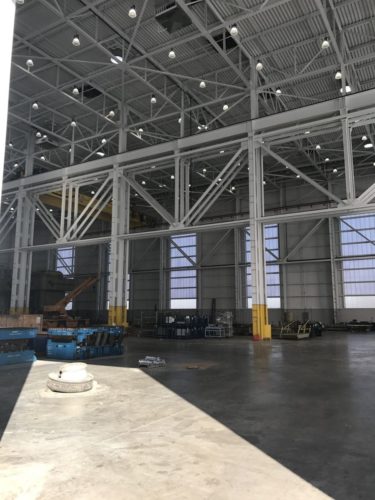

Perhaps the biggest challenge was posed by the sheer height of the existing OEM plant. The plant had a 60-foot structure, which made power distribution installation—particularly for the project’s bus duct distribution system—particularly difficult. Because of the structure’s height, our crews had to perform the majority of work using articulating boom lifts.

The Solution

We were fortunate enough to have a terrific foreman for this job: our foreman was relatively new to the project leadership role at Windemuller, but kept his composure and professionalism even during the most challenging moments. With the help of a seasoned and incredibly supportive crew that maintained laser-like focus throughout the project—especially during the dangerous 60-foot lift work—our team was able to hit deadlines and meet every request of the project for the owner and general contractor.