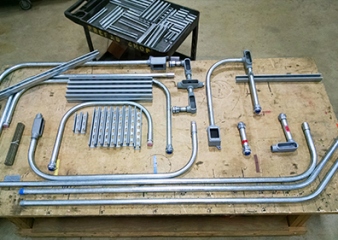

Prefabrication

Since 2006, Windemuller has had a large department dedicated to full-time layout, detailing, and prefabrication. Staffed with qualified electricians who are experts in this field, we are constantly improving techniques and developing innovative ways to maintain our status as a leader in our industry.

Saving You Time and Money

Electrical prefabrication ensures satisfaction for Windemuller customers and general contractors. By pre-planning, detailing projects, and implementing best practices, we maximize quality and continuity and reduce completion times. Our contractors see increased profit margins and customers or owners realize decreased expenses.

By supplying the electrical installation team with systems prior to installation, prefab can increase project efficiency and eliminate waiting on materials, so that even the most fast-tracked projects can be completed on schedule.

Our Equipment

- Drill Press

- Electric Metal Clad Cable Splitter

- Hydraulic Bracket Bender

- Hydraulic Press

- Large Horizontal Ban Saw

- Pneumatic Tools

- Plasma Cutter

- Power Conduit Benders

- Power Conduit Threaders

- Power Reamer

- Production Work Tables

- Spray Paint Booth

- Wire Mig and Tig Welder

- Wire Payout Racks

Meet the Team Lead

Scot kicked off his career in the construction industry in 1992 and now leads the Construction department. He enjoys solving our customer's challenges and helping our team provide great service to our clients.

Scot DeYoung VP of Construction