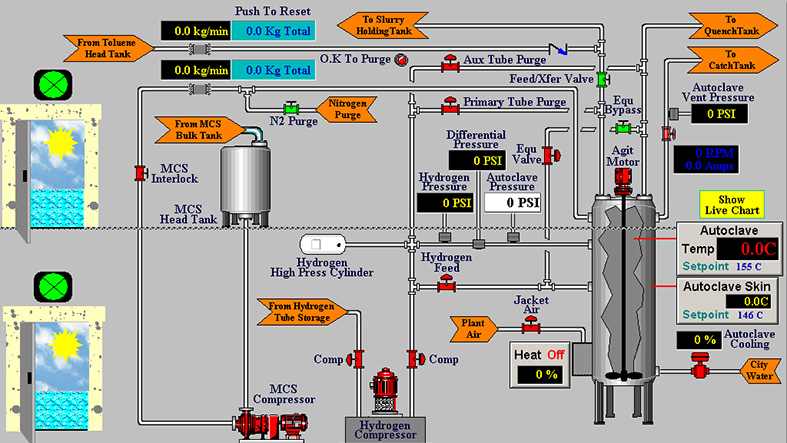

HMI / SCADA Programming

SCADA systems (supervisory control and data acquisition) are essential for almost all process markets, from chemical to petroleum, oil and gas to pharmaceuticals. Allow Windemuller’s Automation department to provide you with the information and control that you need to make your system operate smoothly and efficiently. We have skilled automation engineers that can control your complex systems to enable easy operation for your staff. Leverage our years of experience to improve your operation.

Our Equipment

We offer custom software modules which interface via .Net to major SCADA systems. Highlights include:

- Various PLC Hardware with Allen Bradley and Opto22 being a specialty

- Custom Wonderware and Rockwell Automation RSView

- Custom .Net interfaces to Wonderware ArchestrA

- Historian and Alarming packages including customized packages

- Development of loop diagrams and installation drawings

- Commissioning, startup, and loop tuning services

- Server development using virtual machines

Key Capabilities

- Data collection, system connectivity

- HMI visualization and SCADA

- Advanced trending and reporting

- MES and batching

- Integration with Laboratory Information Management Systems (LIMS), Maintenance Management , ERP and other systems

Key Benefits

- Reduce waste

- Rework and process variability

- Process optimization

- Quality, compliance improvements

- Performance and productivity

Meet the Team Lead

James started his career in the trades back in 1990 and has since moved his way up to the head of the Automation department. James enjoys visiting job sites and helping customers find unique solutions to their everyday challenges.

James Foster Senior Automation Manager